- Company

- Services

- Products

- Spare Parts

- Logistics

- Training/Classes

- Contact

- Careers

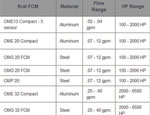

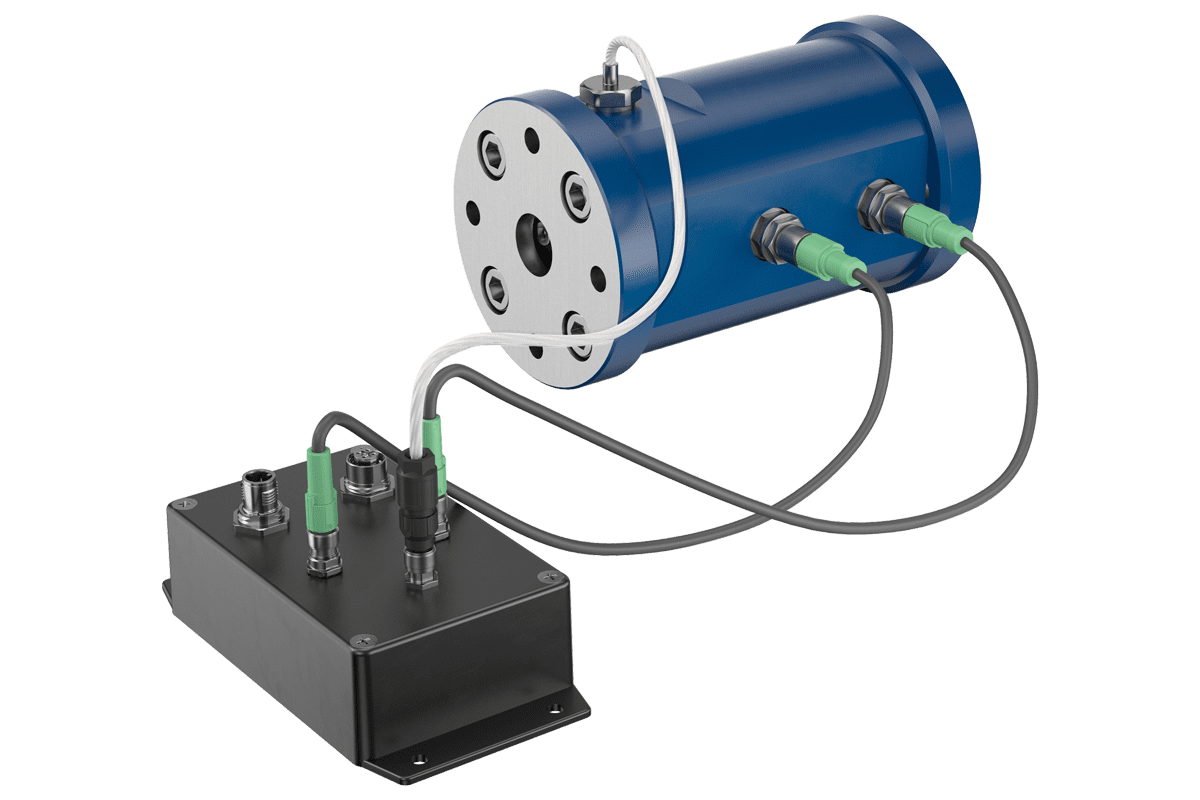

KRAL Fuel Consumption Measurement Systems (FCM) are ideally suited for marine and power generation fuel measurement. Fuel consumption value is an indicator of optimum engine tuning. Reducing speeds of ocean-going vessels and improved engine tuning can save as much as 10% on fuel. KRAL FCM Systems are reliable regulatory monitoring devices to document fuel usage for emissions control air permit reports.

KRAL FCM verify the effectiveness of fuel-saving solutions:

KRAL FCM verify the effectiveness of fuel-saving solutions:

KRAL three screw pumps have clear technical advantages.

When selecting and dimensioning a three screw pump, the pumped liquid, the operating conditions, the installation site as well as the standards, guidelines and directives have to be taken into consideration. A wealth of knowledge is required in order to avoid errors.

High power density

Space for setting up or installing three screw pumps is expensive or often short. KRAL three screw pumps offer high delivery rates at small space requirements in comparison to other pump types.

Good control capabilities

The delivery rate of a three screw pump depends strongly on the speed. If the delivery rate has to be varied, a controller has to change the rotational speed. The complexity of the controller design depends on the delivery rate characteristics of the screw pump. In contrast to many other functional principles, KRAL three screw pumps have linear delivery rate characteristics. Therefore they can be controlled simply and inexpensively by means of a frequency converter.

Low-pulsation transporting

Pressure pulsations of the liquid can damage the three screw pump, the system and the pumped liquid. The strength of the pulsation depends on the functional principle of the pump. Piston and gear pumps cause considerably more pulsations than a three screw pump. KRAL three screw pumps feed product-conservingly. The pumped liquid is not pressed, there are no pressure pulses that can damage the piping and other components or trigger vibrations. In addition, KRAL three screw pumps are very quiet.

Full service locations in Southeast, the Gulf Coast, and the Pacific Northwest, plus a network of local representatives throughout the Americas and the Caribbean.

Estamos disponible para servirle

Instalaciones de servicio completo en el Sureste; Costa Noroeste, y El Golfo. Además una red de agentes en

América Latina y el Caribe.

Please complete the form below. Non-Emergency Requests Only.

Specializing in turnkey engine services, control systems, and engineered solutions for the Marine, Industrial, Energy, and Defense/Government Sectors, MSHS is ready to serve you!